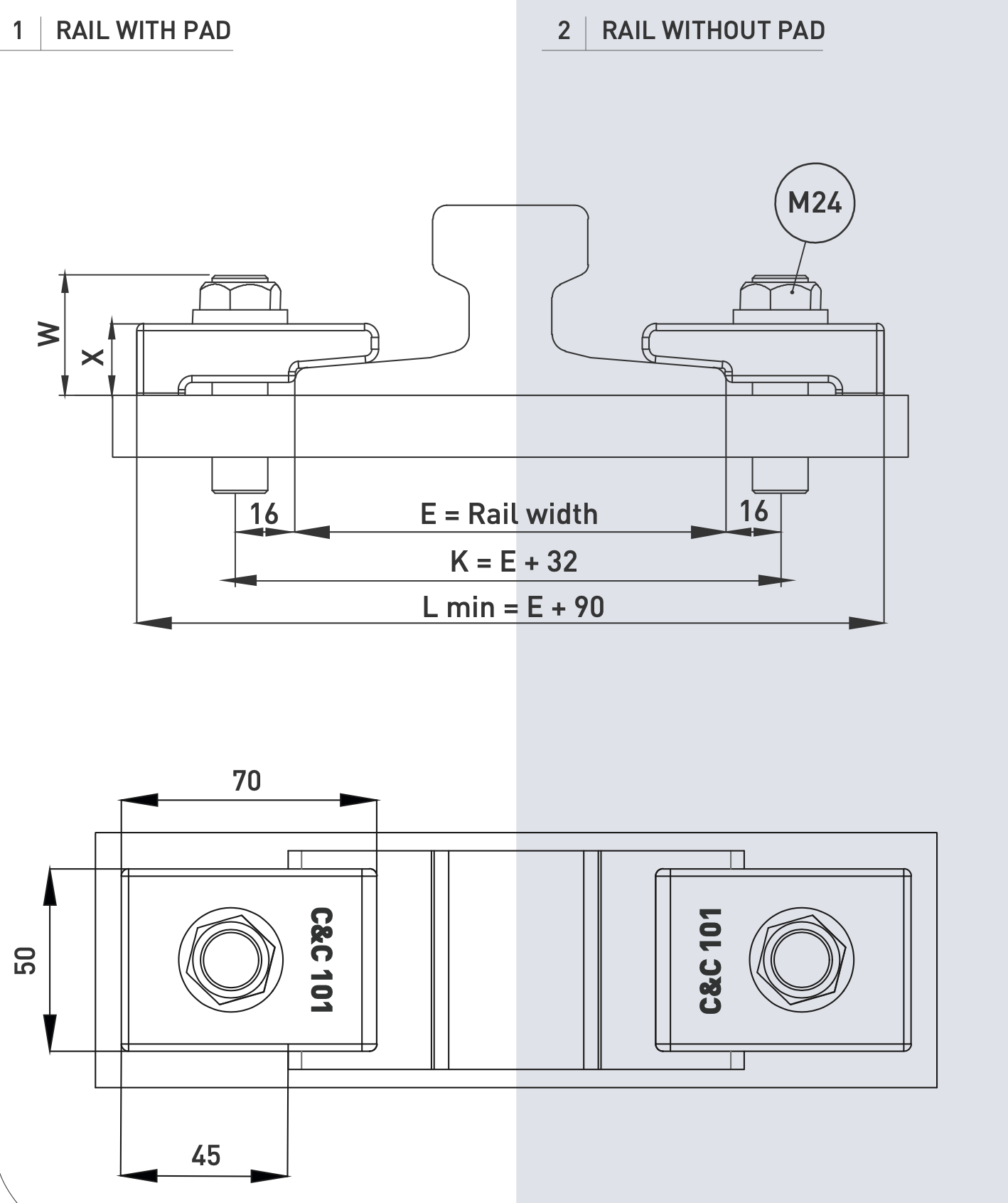

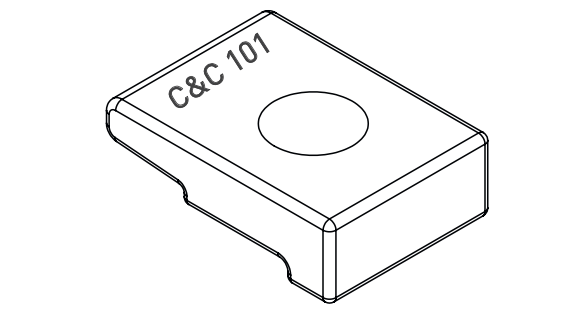

C&C 101 Bolt-on Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 101 | 22 | - | 48 | - | 0,365 |

ASSEMBLY INSTRUCTIONS

The main component is first placed onto the bolt against the rail, and then a special washer is placed on top of the main component. The nut is tightened by hand. For a tighter fit, a hammer is used. After the main component is seated, an electric or pneumatic wrench is used to tighten the nut. For full assembly instructions, please contact C&C.

1· The C&C 101 bolt-on rail clip is made from a forged part and its special design facilitates assembly.

2· Clips can be chosen with or without pads for rails.

3· The main part is locked onto the rail with an M24 bolt.

· Maximum side load: 60 kN

· Bolt: M24 Grade 8.8

· Tightening Torque: 200 Nm

· Steel Quality: St52-3

| Type | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A45 | 45 | 55 | 125 | 101 | - |

| A55 | 55 | 65 | 150 | 101 | - |

| A65 | 65 | 75 | 175 | - | - |

| A75 | 75 | 85 | 200 | - | - |

| A100 | 100 | 95 | 200 | - | - |

| A120 | 120 | 105 | 220 | - | - |

| A150 | 150 | 150 | 220 | - | - |

| S10 | 32 | 70 | 58 | - | - |

| S14 | 38 | 80 | 70 | - | - |

| S18 | 43 | 93 | 82 | - | - |

| S20 | 44 | 100 | 82 | 101 | - |

| S24 | 53 | 115 | 90 | 101 | - |

| S30 | 60.3 | 108 | 108 | 101 | - |

| S31 | 56 | 125 | 106 | - | - |

| S33 | 65 | 145 | 135 | 101 | - |

| S41 A | 67 | 138 | 125 | 101 | - |

| S49 | 67 | 149 | 125 | 101 | - |

| 54 E1 (UIC54) | 70 | 159 | 140 | - | - |

| 60 E1 (UIC60) | 72 | 172 | 150 | - | - |

C&C 106 Welded Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 106/35/10 | 19 | 35 | 55 | 10 | 1,020 |

| C&C 106/35/16 | 19 | 35 | 55 | 16 | 1,100 |

| C&C 106/35/18 | 19 | 35 | 55 | 18 | 1,150 |

ASSEMBLY INSTRUCTIONS

Weld the base of the clip along its entire circumference, except for the side closest and parallel to the rail, with a 4 mm edge thickness. Use low hydrogen electrodes for welding. Recommended electrodes: AWS E7018 or E7028. The clip base is made of weldable quality steel. For continuous welding requirements, please contact us.

· Lateral adjustment: 15 mm

· Bolt: M20 Quality 8.8

· Tightening Torque: 300 Nm

· Steel Quality: St52-3

2· Rubber-nosed upper part

3· Special M20 bolt

4· Weldable lower part

Flanged nuts can be used upon request. Please contact us for the use of flanged nuts.

2· Clips can be used for rails with or without pads.

3· The two main parts are locked together with a special bolt.

4· The rubber nose increases the tolerance of rail support structures, reduces stress at connections, and helps stabilize the rail better.

| Type | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A65 | 65 | 75 | 175 | 106/35/18 | 106/35/10 |

| A75 | 75 | 85 | 200 | 106/35/16 | 106/35/10 |

| A100 | 100 | 95 | 200 | 106/35/16 | 106/35/10 |

| 39 E1 | 63,5 | 133,4 | 117,5 | 106/35/18 | 106/35/10 |

| 45 E1 | 66,7 | 142,9 | 127 | 106/35/18 | 106/35/10 |

| 50 E2 | 72 | 151 | 140 | 106/35/16 | 106/35/10 |

| 56 E1 | 69,85 | 158,75 | 140 | 106/35/16 | 106/35/10 |

| UIC 54 | 70 | 159 | 140 | 106/35/16 | 106/35/10 |

| UIC 60 | 72 | 172 | 150 | 106/35/16 | 106/35/10 |

| S30 | 60,3 | 108 | 108 | 106/35/18 | 106/35/10 |

| S33 | 58 | 134 | 105 | 106/35/18 | 106/35/10 |

| S41 A | 67 | 138 | 125 | 106/35/18 | 106/35/10 |

| S49 | 67 | 149 | 125 | 106/35/16 | 106/35/10 |

| KP70 | 70 | 120 | 120 | 106/35/16 | 106/35/10 |

C&C 205 Welded Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 205/35/12 | 18 | 35 | 45 | 12 | 1,420 |

| C&C 205/35/18 | 18 | 35 | 45 | 18 | 1,440 |

| C&C 205/35/22 | 18 | 35 | 45 | 22 | 1,490 |

ASSEMBLY INSTRUCTIONS

Weld the clip base with a 5 mm throat thickness weld around the entire perimeter, except for the side closest and parallel to the rail. Use low-hydrogen electrodes for welding. Recommended electrodes: AWS E7018 or E7028. The clip base is made from weldable quality steel. For continuous welding requirements, please contact us.

1. C&C 205 welded rail clips are made of two forged parts, upper and lower, and offer easy assembly thanks to their special design.

2. Clips can be preferred for either padded or non-padded rails.

3. The two main parts are locked together with a special bolt.

4. The rubber nose increases the tolerance of rail support structures, reduces stress at connections, and ensures better rail fixation.

· Maximum lateral load: 170 kN

· Lateral adjustment: 8 mm

· Bolt: M16 Quality 8.8

· Tightening Torque: 175 Nm

· Steel Quality: St52-3

1. Nut and washer M16

2. Rubber-nosed upper part

3. Special bolt M16

4. Weldable lower part

Flanged nuts can be used upon request. For the use of flanged nuts, please contact us.

| Type | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A45 | 45 | 55 | 125 | 205/35/22 | 205/35/18 |

| A55 | 55 | 65 | 150 | 205/35/22 | 205/35/18 |

| A65 | 65 | 75 | 175 | 205/35/22 | 205/35/18 |

| A75 | 75 | 85 | 200 | 205/35/22 | 205/35/18 |

| A100 | 100 | 95 | 200 | 205/35/22 | 205/35/12 |

| A120 | 120 | 105 | 220 | 205/35/18 | 205/35/12 |

| S49 | 67 | 149 | 125 | 205/35/22 | 205/35/12 |

| S54 | 67 | 154 | 125 | 205/35/18 | 205/35/12 |

| UIC54 | 70 | 159 | 140 | 205/35/22 | 205/35/12 |

| UIC60 | 72 | 172 | 150 | 205/35/22 | 205/35/12 |

| S41A | 67 | 138 | 125 | 205/35/22 | 205/35/18 |

| 50E2 | 72 | 151 | 140 | 205/35/22 | 205/35/12 |

| P43 | 70 | 140 | 114 | 205/35/18 | 205/35/12 |

| P50 | 72 | 152 | 132 | 205/35/18 | 205/35/12 |

| P65 | 73 | 180 | 150 | 205/35/18 | 205/35/12 |

| KP70 | 70 | 120 | 120 | 205/35/22 | 205/35/12 |

| KP80 | 80 | 130 | 130 | 205/35/22 | 205/35/12 |

| KP100 | 100 | 150 | 150 | 205/35/18 | 205/35/12 |

| CR108 | 65,1 | 131,8 | 131,8 | 205/35/22 | 205/35/12 |

| CR135 | 87,3 | 146,1 | 131,8 | 205/35/18 | 205/35/12 |

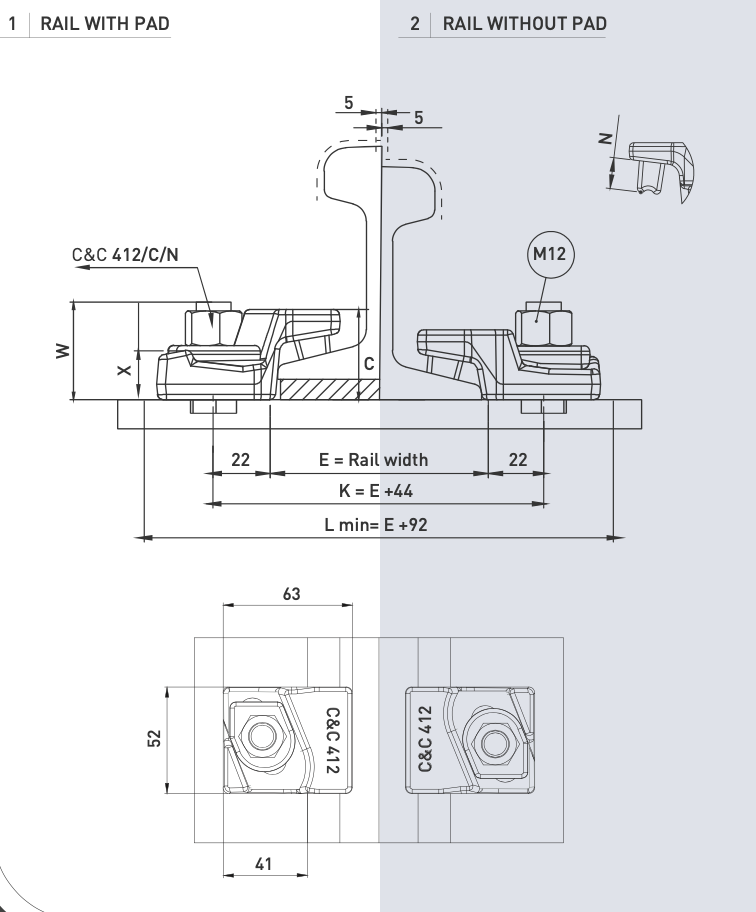

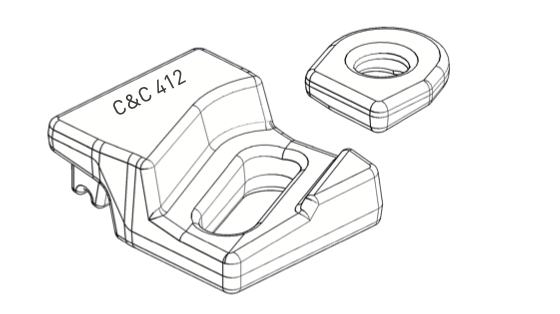

C&C 412 Bolted Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 412/24/12 | 16 | 24 | 34 | 12 | 0,300 |

| C&C 412/31/12 | 16 | 31 | 34 | 12 | 0,340 |

ASSEMBLY INSTRUCTIONS

The main component is first placed against the rail and then a special washer is placed on top of the main component. The nut is tightened by hand. For a firmer contact, a hammer can be used. Once the main component is in place, use an electric or pneumatic wrench to tighten the nut. For complete assembly instructions, please contact C&C.

1· The C&C 412 bolted rail clip is made from a forged piece and offers easy assembly thanks to its special design.

2· Clips can be used for padded or unpadded rails.

3· The main part locks onto the rail with an M12 bolt and special washer.

4· The rubber nose increases the tolerance of the rail support structures, reduces stress at the connections, and ensures better rail fixation.

· Maximum side load: 30 kN

· Lateral adjustment: 10 mm

· Bolt: M12 Quality 8.8

· Tightening Torque: 85 Nm

· Steel Quality: St52-3

| Type | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A45 | 45 | 55 | 125 | 412/24/12 | 412/31/12 |

| S7 | 25 | 65 | 50 | 412/24/12 | 412/31/12 |

| S10 | 32 | 70 | 58 | 412/24/12 | 412/31/12 |

| S14 | 38 | 80 | 70 | 412/24/12 | 412/31/12 |

| S18 | 43 | 92 | 82 | 412/24/12 | 412/31/12 |

| S20 | 44 | 100 | 82 | 412/24/12 | 412/31/12 |

| S24 | 53 | 115 | 90 | 412/24/12 | 412/31/12 |

| 9 KG | 32 | 64 | 64 | 412/24/12 | 412/31/12 |

| 12 KG | 43 | 70 | 70 | 412/24/12 | 412/31/12 |

| 15 KG | 43 | 80 | 80 | 412/24/12 | 412/31/12 |

| 22 KG | 51 | 94 | 94 | 412/24/12 | 412/31/12 |

| ASC20 | 34 | 66 | 60 | 412/24/12 | 412/31/12 |

| ASC25 | 38 | 69 | 69 | 412/24/12 | 412/31/12 |

| ASC30 | 43 | 30 | 79 | 412/24/12 | 412/31/12 |

| ASC40 | 48 | 40 | 89 | 412/24/12 | 412/31/12 |

C&C 414 Bolted Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 414/31/10,5 | 14 | 31 | 35 | 10,5 | 0,380 |

| C&C 414/31/16 | 14 | 31 | 35 | 16 | 0,390 |

ASSEMBLY INSTRUCTIONS

The main component is placed on the rail against the bolt, and then the special washer is placed over the main component. The nut is tightened by hand. For a firmer contact, a hammer is used. After the main component is in place, use an electric or pneumatic wrench to tighten the nut. For complete assembly instructions, please contact C&C.

1· The C&C 414 bolted rail clip is made from a forged part and offers easy assembly due to its special design.

2· Clips can be preferred for rails with or without pads.

3· The main part is locked to the rail with an M16 bolt and a special washer.

4· The rubber nose increases the tolerance of the rail support structures, reduces stress in the connections, and ensures better rail fixation.

· Maximum lateral load: 60 kN

· Lateral adjustment: 10 mm

· Bolt: M16 Grade 8.8

· Tightening Torque: 200 Nm

· Steel Grade: St52-3

| Type | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A45 | 45 | 55 | 125 | 414/31/16 | 414/31/10,5 |

| A55 | 55 | 65 | 150 | 414/31/16 | 414/31/10,5 |

| A65 | 65 | 75 | 175 | 414/31/16 | 414/31/10,5 |

| S18 | 43 | 93 | 82 | 414/31/16 | 414/31/10,5 |

| S20 | 44 | 100 | 82 | 414/31/16 | 414/31/10,5 |

| S24 | 53 | 115 | 90 | 414/31/16 | 414/31/10,5 |

| S30 | 60,3 | 108 | 108 | 414/31/16 | 414/31/10,5 |

| S31 | 56 | 125 | 106 | 414/31/18 | 414/31/10,5 |

| S33 | 58 | 134 | 105 | 414/31/16 | 414/31/10,5 |

| S41 A | 67 | 138 | 125 | 414/31/16 | 414/31/10,5 |

| P24 | 51 | 107 | 92 | 414/31/16 | 414/31/10,5 |

| P43 | 70 | 140 | 114 | 414/31/16 | - |

| P50 | 72 | 152 | 132 | 414/31/16 | - |

| AFNOR 24 | 50 | 110 | 100 | 414/31/16 | 414/31/10,5 |

| AFNOR 30 | 56 | 125,5 | 106 | 414/31/16 | 414/31/10,5 |

| ASCE 60 | 50 | 110 | 100 | 414/31/16 | 414/31/10,5 |

| ASCE 80 | 63,5 | 127 | 127 | 414/31/16 | 414/31/10,5 |

| ASCE 85 | 65,1 | 131,8 | 131,8 | 414/31/16 | 414/31/10,5 |

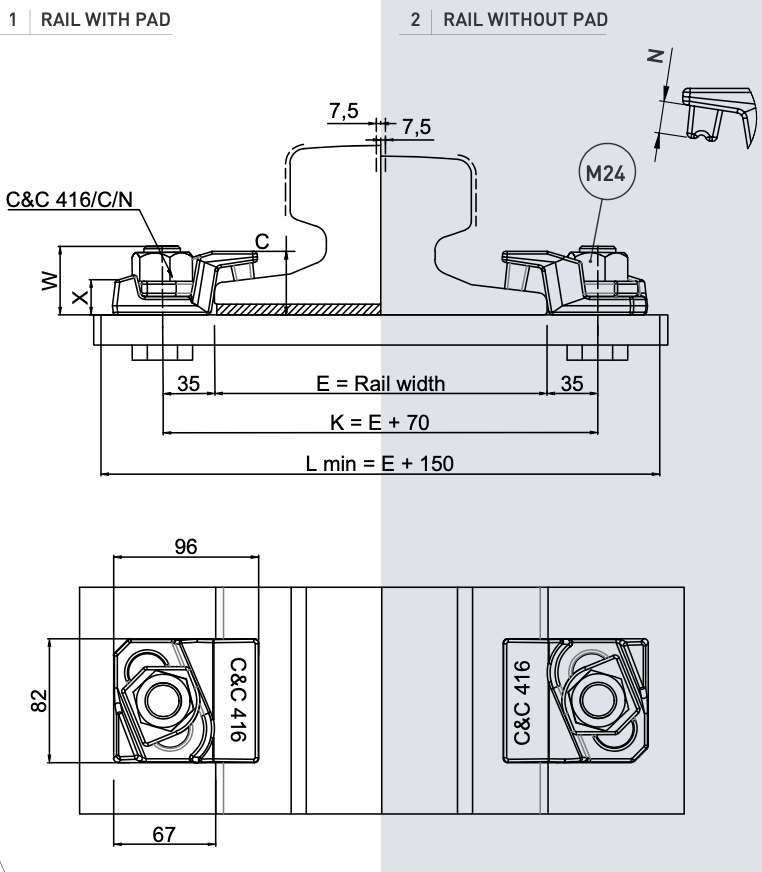

C&C 416 Bolt Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 416/42/9 | 22 | 42 | 45 | 9 | 0,900 |

| C&C 416/42/14 | 22 | 42 | 45 | 14 | 0,915 |

| C&C 416/42/21 | 22 | 42 | 45 | 21 | 0,930 |

INSTALLATION INSTRUCTIONS

The main component is first placed against the rail with a bolt, and then a special washer is placed over the main component. The nut is tightened by hand. For a tighter contact, a hammer is used. After the main component is in place, use an electric or pneumatic wrench to tighten the nut. Please contact C&C for complete installation instructions.

1. C&C 416 bolt rail clip is made from a forged piece and provides easy installation thanks to its special design.

2. Clips can be used for rail types with or without pads.

3. The main part is locked to the rail with an M24 bolt and special washer.

4. The rubber nose increases the tolerance of rail support structures, reduces stress at the connections, and helps better stabilize the rail.

· Maximum lateral load: 160 kN

· Lateral adjustment: 15 mm

· Bolt: M24 Quality 8.8

· Tightening torque: 550 Nm

· Steel quality: St52-3

| Type | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A100 | 100 | 95 | 200 | 416/42/21 | 416/42/19 |

| A120 | 120 | 105 | 220 | 416/42/21 | 416/42/14 |

| A150 | 150 | 150 | 220 | 416/42/21 | 416/42/14 |

| CR73 | 100 | 135 | 140 | 416/42/21 | 416/42/14 |

| CR100 | 120 | 150 | 155 | 416/42/21 | 416/42/9 |

| CR104 | 63,5 | 127 | 127 | 416/42/21 | 416/42/14 |

| CR105 | 65,1 | 131,8 | 131,8 | 416/42/21 | 416/42/14 |

| CR135 | 79,4 | 146,1 | 131,8 | 416/42/21 | 416/42/14 |

| CR171 | 101,6 | 152,4 | 152,4 | 416/42/21 | 416/42/14 |

| CR175 | 102,4 | 152,4 | 152,4 | 416/42/21 | 416/42/14 |

| MRS73 | 70 | 157 | 146 | 416/42/21 | 416/42/9 |

| MRS87A | 101,6 | 152,4 | 152,4 | 416/42/21 | 416/42/14 |

| P50 | 72 | 152 | 132 | 416/42/21 | 416/42/14 |

| P65 | 73 | 180 | 150 | 416/42/21 | 416/42/14 |

| KP100 | 100 | 150 | 150 | 416/42/21 | 416/42/14 |

| KP120 | 120 | 170 | 170 | 416/42/21 | 416/42/14 |

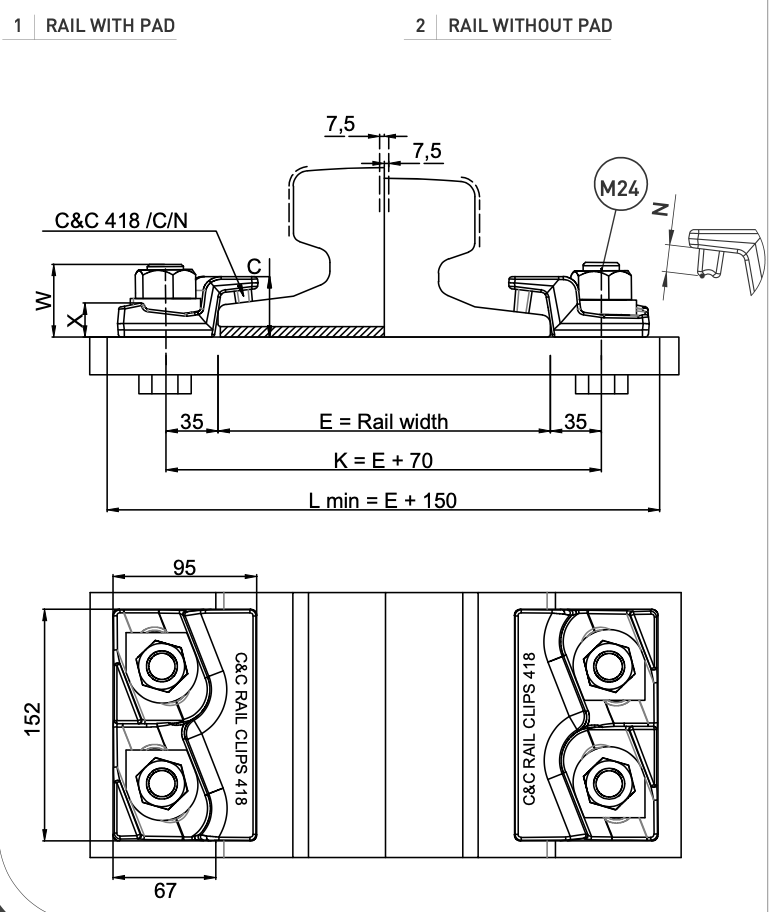

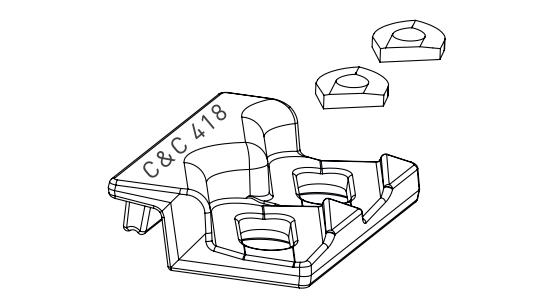

C&C 418 Bolt-on Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 418/40/12 | 21 | 40 | 50 | 12 | 2,350 |

| C&C 418/40/18 | 21 | 40 | 50 | 18 | 2,450 |

INSTALLATION INSTRUCTIONS

The main component is first placed against the rail, followed by placing a special washer on top of the main component. The nut is tightened by hand. A hammer is used for a firmer contact. After the main component is in place, an electric or pneumatic wrench is used to tighten the nut. For full installation instructions, please contact C&C.

1. The C&C 418 bolt-on rail clip is made from a forged piece and offers easy installation with its special design.

2. Clips can be used for rails with or without pads.

3. The main part locks onto the rail with a special bolt.

4. The rubber nose increases the tolerance of rail support structures, reduces stress at connections, and helps better fixation of the rail.

· Maximum lateral load: 250 kN

· Lateral adjustment: 15 mm

· Bolt: M24 Quality 8.8

· Tightening Torque: 550 Nm

· Steel Quality: St52-3

| Type | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A120 | 120 | 105 | 220 | 418/40/18 | 418/40/12 |

| A150 | 150 | 150 | 220 | 418/40/18 | 418/40/12 |

| CR73 | 100 | 135 | 140 | 418/40/18 | 418/40/12 |

| CR104 | 63,5 | 127 | 127 | 418/40/18 | 418/40/12 |

| CR135 | 79,4 | 146,1 | 131,8 | 418/40/18 | 418/40/12 |

| CR171 | 101,6 | 152,4 | 152,4 | 418/40/18 | 418/40/12 |

| CR175 | 102,4 | 152,4 | 152,4 | 418/40/18 | 418/40/12 |

| MRS73 | 70 | 157 | 146 | 418/40/18 | 418/40/12 |

| MRS86 | 102 | 102 | 165 | 418/40/18 | 418/40/12 |

| MRS87A | 101,6 | 152,4 | 152,4 | 418/40/18 | 418/40/12 |

| KP100 | 100 | 150 | 150 | 418/40/18 | 418/40/12 |

| KP120 | 120 | 170 | 170 | 418/40/18 | 418/40/12 |

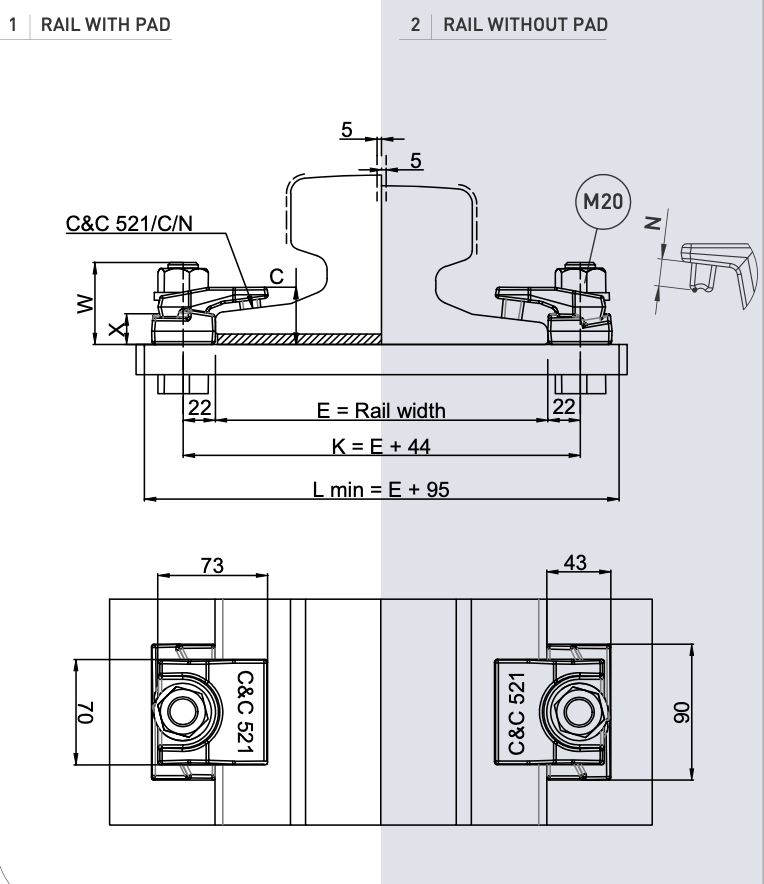

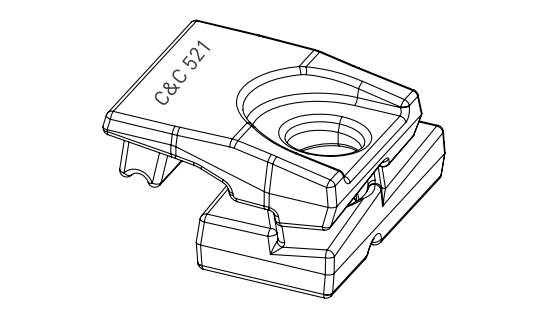

C&C 521 Bolt Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 521/38/14 | 18 | 38 | 55 | 14 | 0,790 |

| C&C 521/38/20 | 18 | 38 | 55 | 20 | 0,800 |

ASSEMBLY INSTRUCTIONS

The main component is first placed on the rail against the bolt, and then the special washer is placed on top of the main component. The nut is tightened by hand. A hammer is used for a tighter fit. After the main component is positioned, use an electric or pneumatic wrench to tighten the nut. For full assembly instructions, please contact C&C.

1· C&C 521 bolt rail clip is made from a forged piece and offers easy assembly thanks to its special design.

2· Clips can be used for padded or non-padded rails.

3· The main component is locked to the rail with a special bolt.

4· The rubber nose increases the tolerance of the rail support structures, reduces stress at the connections, and ensures better rail fixation.

· Maximum lateral load: 90 kN

· Lateral adjustment: 10 mm

· Bolt: M20 Quality 8.8

· Tightening Torque: 390 Nm

· Steel Quality: St52-3

| RAIL TYPE | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A65 | 65 | 75 | 175 | 521/38/20 | 521/38/14 |

| A75 | 75 | 85 | 200 | 521/38/20 | 521/38/14 |

| A100 | 100 | 95 | 200 | 521/38/20 | 521/38/14 |

| A120 | 120 | 105 | 220 | 521/38/20 | 521/38/14 |

| CR105 | 65,1 | 131,8 | 131,8 | 521/38/20 | 521/38/14 |

| S33 | 58 | 134 | 105 | 521/38/20 | 521/38/14 |

| S41 A | 67 | 138 | 125 | 521/38/20 | 521/38/14 |

| S49 | 67 | 149 | 125 | 521/38/20 | 521/38/14 |

| S54 | 67 | 154 | 125 | 521/38/20 | 521/38/14 |

| 50 E2 | 72 | 151 | 140 | 521/38/20 | 521/38/14 |

| UIC 54 | 70 | 159 | 140 | 521/38/20 | 521/38/14 |

| UIC 60 | 72 | 172 | 150 | 521/38/20 | 521/38/14 |

| 56 E1 | 69,85 | 158,75 | 140 | 521/38/20 | 521/38/14 |

| P43 | 70 | 140 | 114 | 521/38/20 | 521/38/14 |

| P50 | 72 | 152 | 132 | 521/38/20 | 521/38/14 |

C&C 4018 Bolt Type Rail Clips

| CLIPS NO | X | W | Weight (Kg) |

|---|---|---|---|

| C&C 4018 | 18 | 41 | 0,385 |

MOUNTING INSTRUCTIONS

The main component is first placed against the rail and bolt, then the special washer is placed on top of the main component. The nut is tightened by hand. For a tighter fit, a hammer can be used. After the main component is in place, use an electric or pneumatic wrench to tighten the nut. For detailed assembly instructions, please contact C&C.

1. C&C 4018 bolt type rail clip is made from a forged piece and offers easy installation thanks to its special design.

2. Clips can be used for rail with or without pads.

3. The main component is locked to the rail with an M20 bolt.

· Maximum lateral load: 60 kN

· Lateral adjustment: 6 mm

· Bolt: M20 Quality 8.8

· Tightening Torque: 220 Nm

· Steel Quality: St52-3

| Type | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A45 | 45 | 55 | 125 | 4018 | - |

| A55 | 55 | 65 | 150 | 4018 | - |

| A65 | 65 | 75 | 175 | 4018 | - |

| A75 | 75 | 85 | 200 | - | - |

| A100 | 100 | 95 | 200 | - | - |

| A120 | 120 | 105 | 220 | - | - |

| A150 | 150 | 150 | 220 | - | - |

| S10 | 32 | 70 | 58 | 4018 | - |

| S14 | 38 | 80 | 70 | 4018 | - |

| S18 | 43 | 93 | 82 | 4018 | - |

| S20 | 44 | 100 | 82 | 4018 | - |

| S24 | 53 | 115 | 90 | 4018 | - |

| S30 | 60,3 | 108 | 108 | 4018 | - |

| S31 | 56 | 125 | 106 | - | - |

| S33 | 65 | 145 | 135 | 4018 | - |

| S41 A | 67 | 138 | 125 | 4018 | - |

| S49 | 67 | 149 | 125 | - | - |

| 54 E1 (UIC54) | 70 | 159 | 140 | - | - |

| 60 E1 (UIC60) | 72 | 172 | 150 | - | - |

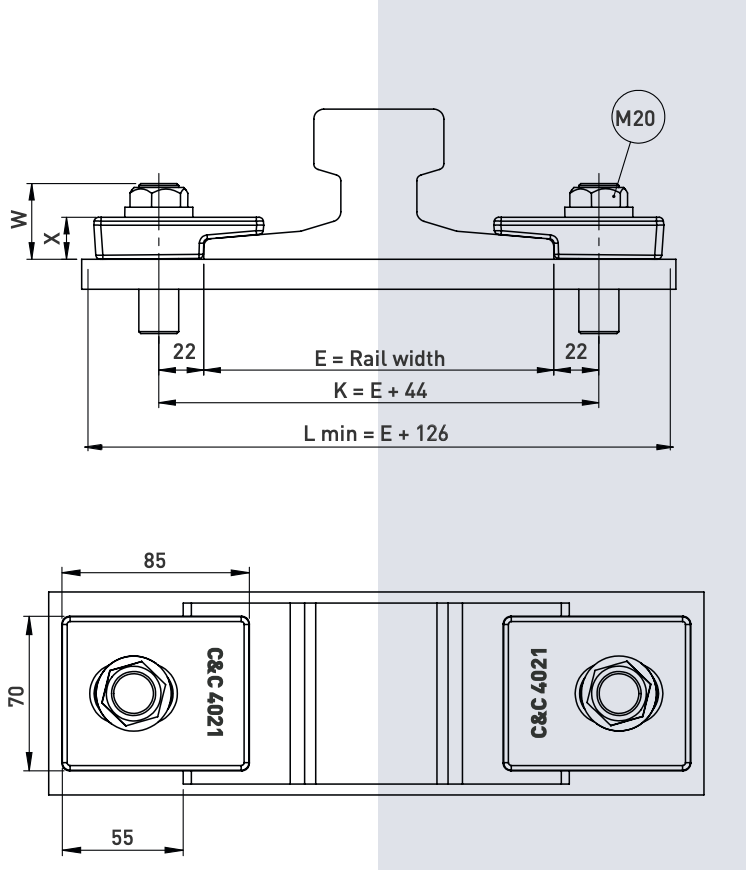

C&C 4021 Bolt Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 4021 | 21 | - | 44 | - | 0,650 |

MOUNTING INSTRUCTIONS

The main component is first placed against the rail using the bolt and then the special washer is placed on top of the main component. The nut is hand-tightened. A hammer can be used for a firmer contact. Once the main component is in place, use an electric or pneumatic wrench to tighten the nut. For full assembly instructions, please contact C&C.

1· C&C 4021 bolt rail clip is made from a forged piece and offers easy assembly thanks to its special design.

2· Clips can be used for padded or non-padded rails.

3· The main part is locked onto the rail with an M20 bolt.

· Maximum lateral load: 70 kN

· Lateral adjustment: 8 mm

· Bolt: M20 Grade 8.8

· Tightening Torque: 320 Nm

· Steel Grade: St52-3

| RAIL TYPE | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A45 | 45 | 55 | 125 | - | - |

| A55 | 55 | 65 | 150 | - | - |

| A65 | 65 | 75 | 175 | 4021 | - |

| A75 | 75 | 85 | 200 | 4021 | - |

| A100 | 100 | 95 | 200 | - | - |

| A120 | 120 | 105 | 220 | - | - |

| A150 | 150 | 150 | 220 | - | - |

| S10 | 32 | 70 | 58 | - | - |

| S14 | 38 | 80 | 70 | - | - |

| S18 | 43 | 93 | 82 | - | - |

| S20 | 44 | 100 | 82 | - | - |

| S24 | 53 | 115 | 90 | 4021 | - |

| S30 | 60,3 | 128 | 108 | 4021 | - |

| S31 | 56 | 125 | 104 | - | - |

| S33 | 65 | 145 | 135 | 4021 | - |

| S41 A | 67 | 138 | 125 | 4021 | - |

| S49 | 67 | 149 | 125 | 4021 | - |

| 54 E1 (UIC54) | 70 | 159 | 140 | 4021 | - |

| 60 E1 (UIC60) | 72 | 172 | 150 | - | - |

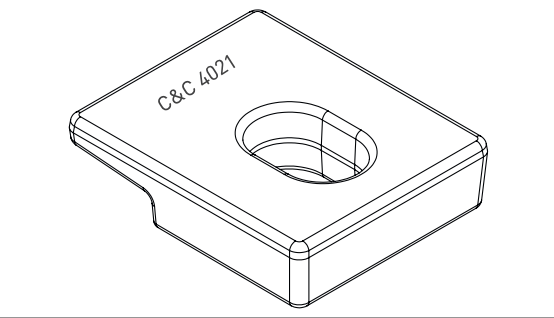

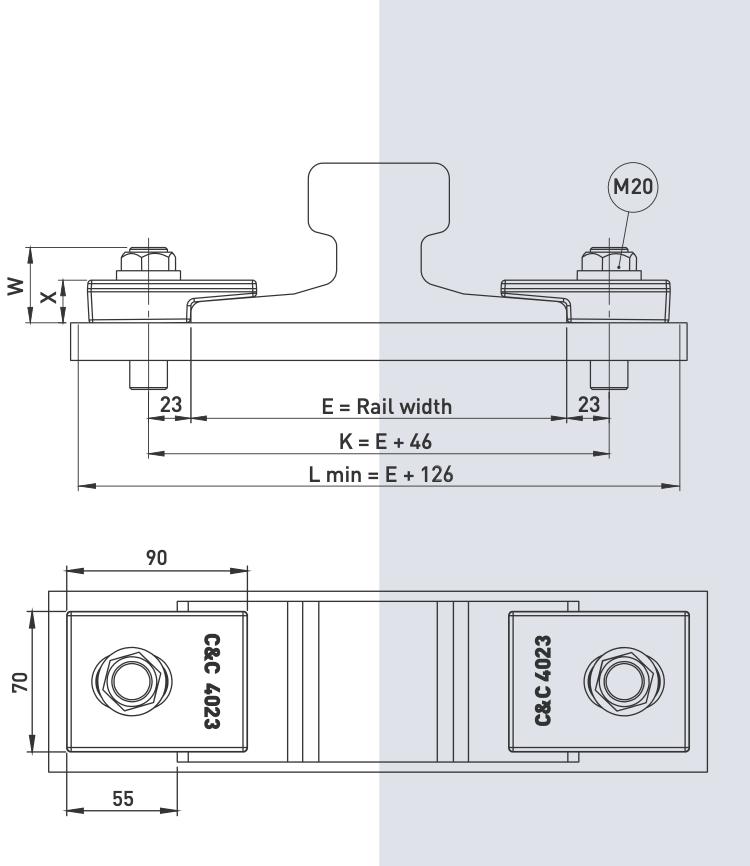

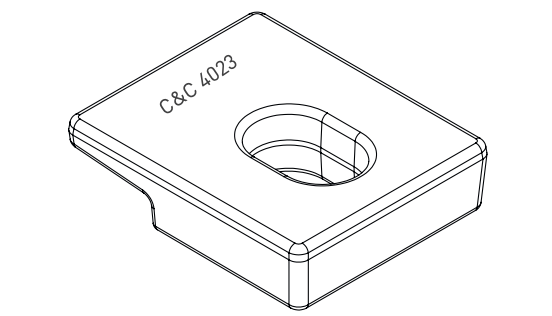

C&C 4023 Bolted Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 4023 | 23 | - | 46 | - | 0,740 |

INSTALLATION INSTRUCTIONS

The main component is first placed against the rail and then the special washer is placed on the main component. The nut is tightened by hand. For a tighter fit, a hammer is used. After the main component is seated, use an electric or pneumatic wrench to tighten the nut. For full installation instructions, please contact C&C.

1. The C&C 4023 bolted rail clip is made from a forged part, and its special design allows for easy installation.

2. Clips can be used for both padded or non-padded rails.

3. The main part is locked to the rail with an M20 bolt.

· Maximum lateral load: 70 kN

· Lateral adjustment: 8 mm

· Bolt: M20 Quality 8.8

· Tightening Torque: 320 Nm

· Steel Quality: St52-3

| RAIL TYPE | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A45 | 45 | 55 | 125 | - | - |

| A55 | 55 | 65 | 150 | - | - |

| A65 | 65 | 75 | 175 | - | - |

| A75 | 75 | 85 | 200 | 4023 | - |

| A100 | 100 | 95 | 200 | 4023 | - |

| A120 | 120 | 105 | 220 | - | - |

| A150 | 150 | 150 | 220 | - | - |

| S10 | 32 | 70 | 58 | - | - |

| S14 | 38 | 80 | 70 | - | - |

| S18 | 43 | 93 | 82 | - | - |

| S20 | 44 | 100 | 82 | - | - |

| S24 | 53 | 115 | 90 | - | - |

| S30 | 60,3 | 108 | 108 | 4023 | - |

| S31 | 56 | 125 | 106 | - | - |

| S33 | 65 | 145 | 135 | 4023 | - |

| S41 A | 54 | 138 | 125 | - | - |

| S49 | 67 | 149 | 125 | 4023 | - |

| 54 E1 (UIC54) | 70 | 159 | 140 | 4023 | - |

| 60 E1 (UIC60) | 72 | 172 | 150 | 4023 | - |

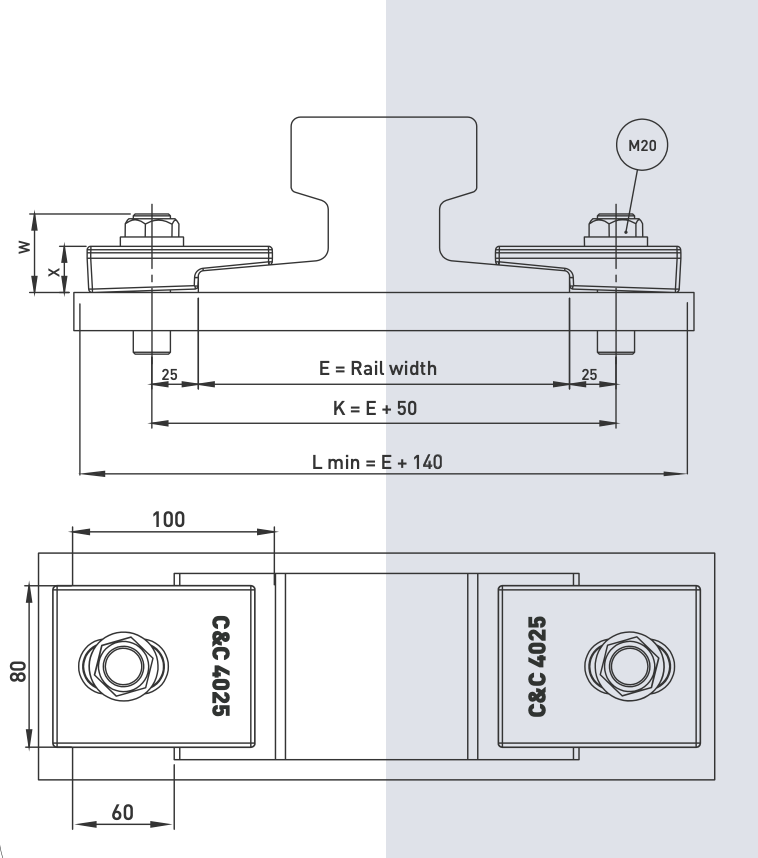

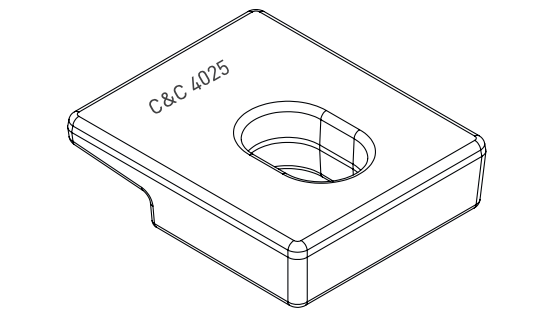

C&C 4025 Bolt Rail Clips

| CLIPS NO | X | C | W | N | Weight (Kg) |

|---|---|---|---|---|---|

| C&C 4025 | 25 | - | 48 | - | 1,000 |

ASSEMBLY INSTRUCTIONS

The main component is first placed onto the rail against the bolt, then a special washer is placed on top of the main component. The nut is tightened by hand. A hammer can be used for a tighter fit. Once the main component is in place, an electric or pneumatic wrench is used to torque the nut. For complete assembly instructions, please contact C&C.

1· The C&C 4025 bolt rail clip is made from forged parts, designed to facilitate easy assembly.

2· Clips can be used for both padded and non-padded rails.

3· The main part is locked onto the rail with an M20 bolt.

· Maximum lateral load 70 kN

· Lateral adjustment 10 mm

· Bolt M20 Grade 8.8

· Tightening torque 320 Nm

· Steel Quality St52-3

| RAIL TYPE | A | B | E | Without Pad | With Pad |

|---|---|---|---|---|---|

| A45 | 45 | 55 | 125 | - | - |

| A55 | 55 | 65 | 150 | - | - |

| A65 | 65 | 75 | 175 | 4025 | - |

| A75 | 75 | 85 | 200 | 4025 | - |

| A100 | 100 | 95 | 200 | 4025 | - |

| A120 | 120 | 105 | 220 | - | - |

| A150 | 150 | 150 | 220 | - | - |

| S10 | 32 | 70 | 58 | - | - |

| S14 | 38 | 80 | 70 | - | - |

| S18 | 43 | 93 | 82 | - | - |

| S20 | 44 | 100 | 82 | - | - |

| S24 | 53 | 115 | 90 | - | - |

| S30 | 60,3 | 108 | 108 | 4025 | - |

| S31 | 56 | 125 | 106 | - | - |

| S33 | 65 | 145 | 135 | 4025 | - |

| S41 A | 67 | 138 | 125 | 4025 | - |

| S49 | 67 | 149 | 125 | - | - |

| 54 E1 (UIC54) | 70 | 159 | 140 | - | - |

| 60 E1 (UIC60) | 72 | 172 | 150 | 4025 | - |